Exoskeletons are wearable devices that can enhance, augment, or assist the worker's posture, motion, or physical activity.

Exoskeletons represent an opportunity for supporting humans at work and addressing the mismatch between physical demands and human capabilities, with the potential for reducing work-related musculoskeletal disorders.

However, despite the explosion of available devices, exoskeletons have not yet gained widespread workplace adoption. In this article, we explore the pros and cons of this technology and its implications for workplace health and safety.

What are exoskeletons?

Exoskeletons are wearable devices that can enhance, augment, or assist the worker’s posture, motion, or physical activity. They consist of structures that are external to the body and aim to, for example, stabilise static or facilitate dynamic movements. They typically target one body region, although there are a few advanced ‘full body’ exoskeletons. The idea is that they work together with the worker’s physical abilities to:

- Reduce biomechanical load on the worker’s joints, and soft tissues – reducing the risk of musculoskeletal disorders

- Reduce the worker’s metabolic exertion – reducing worker fatigue and risk of overexertion

Exoskeletons can be divided into active and passive devices, which offer differing levels of support for the worker.

- Active exoskeletons use force and torque-generating elements such as electric motors, pneumatics, or hydraulics to provide additional strength to the worker.

- Passive exoskeletons use levers, springs, counterbalance forces, and other non-electrical means to support the worker’s posture or movement. Passive exoskeletons redistribute forces to protect specific body regions. The change in user performance results not from additional physical strength but from the ability to maintain positions over a longer period (e.g. overhead work).

Pros and cons of exoskeletons

Over the past five years, plenty of research has been published around the biomechanical effects of exoskeletons, but workplace studies and information on adverse effects are still limited. Here, we summarise some of the reported positives and negatives of exoskeletons.

Positives

- Decreases activation of muscles targeted by the exoskeleton

- Reduces levels of total musculoskeletal discomfort

- Decreases worker fatigue and improves worker endurance

- Decreases the perceived exertion of a task

- Reduces physical stress and strain in terms of metabolic and cardiorespiratory measurements

- Improve the perceived safety and performance of a task

- Increases certain ranges of motion

- Increases hold time when working at shoulder height or above (shoulder exoskeletons)

- Improves sleep and feelings of restfulness

- Lowers work-related medical costs

Negatives

- Increases activity of other muscles (where load is redistributed)

- Causes wearer discomfort due to the straps, belts, and plates holding it onto the body

- Hinders worker mobility and increases feelings of awkwardness

- Increases time pressure and/or time taken during dynamic tasks

- Restraint pressure can exceed the threshold for adequate blood supply, which can lead to pain and tissue damage

- Causes increased concerns around wearer’s safety due to straps getting caught or pulled or getting stuck in tight places

- Decreases certain ranges of motion due to extra bulk and intended restraints

- Decreases the wearer’s ability to recover from slips and trips (leg exoskeletons)

- Fitting is an ongoing problem, especially for women, the very large, or the very small

- Reduction in initial benefits seen over time

Where do exoskeletons fit into the workplace?

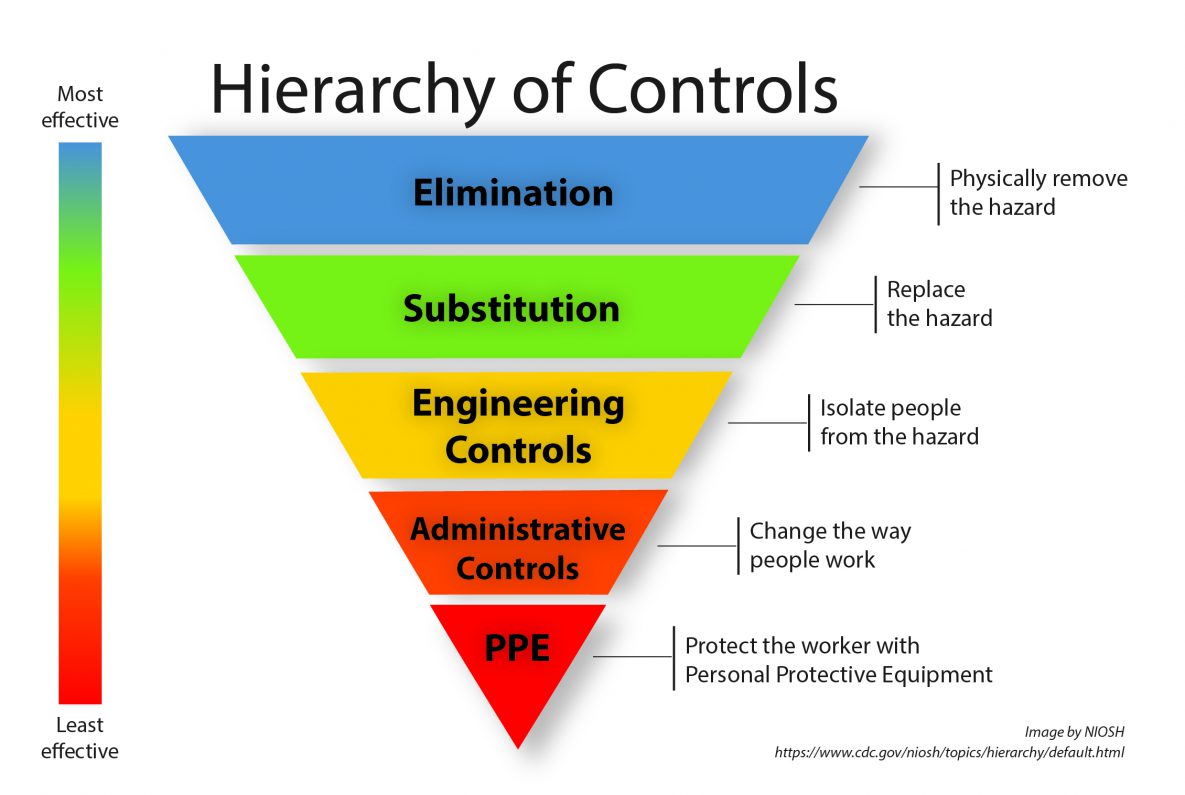

Traditionally, workplace controls to prevent work-related musculoskeletal disorders have focused on reducing biomechanical loads for workers or introducing organisational or technological measures to minimise exposure to severe or repeated loads. The hierarchy of control promotes the best actions to take to reduce or remove hazards, with elimination of the hazard being the most effective and preferred solution. Among large manufacturing sites, elimination is not always feasible, especially since manual work will remain essential for many production chains. Robots cannot achieve the dexterity of humans, and where flexibility, sensorimotor ability, and cognition are relevant, human workers cannot be substituted for automated solutions.

Exoskeletons can be considered an ergonomic control measure, and are considered by most to be an atypical form of PPE (wherein they protect the wearer from internal hazards rather than external hazards). At the same time, exoskeletons can also be categorised as an engineering control because, similar to material handling equipment, it aims to reduce the wearer’s physical effort in executing a task. Industrial examples of this can be seen in the US, where Toyota North America has made it a requirement for their workers to wear exoskeletons as mandatory PPE. At the other end, Dow Chemical has implemented exoskeletons as an engineering control.

Their effectiveness as PPE is currently hard to measure, as the exoskeletons are protecting the wearer from internal musculoskeletal hazards and quantifying this depends so much on the combined uniquenesses of the physical makeup of the wearer, the nature of the work they are doing, and the accommodations afforded by the make or model of the exoskeleton they are using.

There are no guidelines for implementing exoskeletons in workplaces

If exoskeletons were to be deployed as PPE, the idea is that they would be a barrier between the worker and forceful exertions, repetitions, awkward posture, contact stress, and/or vibration. PPE is considered the least effective control because it does not remove the hazard in any way – and injury can still occur if workers don’t use or wear their PPE correctly.

Your workplace will need to develop a system for deploying the devices that includes proper training on wearing it, including donning and doffing the PPE, inspection and replacement of damaged PPE, safe disposal of contaminated PPE and so on. Training should include education on what hazards the exoskeleton is protecting the worker from, as well as the limits of its protection.

As with the introduction of any new tool or technology into the workflow, there are several key considerations to take into account:

- Initial capital cost

- Training for the workers

- Performance of the workers post-implementation

- Changes to the workplace to fully utilise the device

- Response from the unions

- Maintenance and associated consumable supplies

- Inspection and cleaning

- Storage

- Retirement and disposal

Having a standardised process such as risk assessment and task analysis in place will help your company decide whether exoskeletons are worth the investment. Additionally, having standards for holistic ergonomic and safety design and validation will help reduce the chances of transferring the risk from one area of the body to another.

Conclusion

Technology has tradeoffs, and there will be applications where the benefits of exoskeletons outweigh the negatives. For exoskeletons, the main sticking point is whether workers will wear the device. Fit, function, performance, comfort, and even look will be different for each individual worker. Thus, your ROI metrics may have to take on an individualised approach, similar to training, implementing a safety program, or professional development, instead of a site-wide approach such as adding a new production line or automating a particular task.

Exoskeletons will be more successful if they can show that they effectively reduce physical and mental loads, and if they are socially accepted among the workforce. It is therefore recommended that if you’re thinking of implementing exoskeletons, effort is made to gain social support among the workers and expectations are appropriately set on the usability of exoskeletons.

Sign up to our monthly enewsletter

"*" indicates required fields